Introduction

Floating floors have gained popularity among homeowners because they are easy to install, cost-effective, and visually appealing. Floating floors are not glued or nailed to the subfloor like conventional flooring; they “float” across the subfloor based on an interlocking system. However, most homeowners find that their floating floors creak when walked upon, and they wonder if this is normal or a sign of an issue. This blog discusses why floating floors creak, if it is something to worry about, and how to minimize or eliminate these sounds for a more peaceful and comfortable home.

Why Do Floating Floors Creak?

It’s standard for floating floors to produce sounds like creaking, clicking, or popping when walked on. Here are some of the main reasons why this happens:

1. Subfloor Imperfections

An uneven subfloor is the most typical cause of Noise in floating floors. If the subfloor is not level, the floating floor panels will not lie flat and will shift back and forth when you walk upon them. This shifting can create creaking or clicking sounds.

2. Incorrect Installation

If the floating floor is not installed correctly, there is almost no way to avoid Noise. Inadequate alignment of the planks or insufficient expansion gaps can result in friction and pressure between the boards, making them creak when compressed.

3. Insufficient Underlayment

Underlayment is a buffer and cushion between the subfloor and the floating floor. Without underlayment or the improper use of underlayment, the floor will sound hollow or click when it is walked upon.

4. Moisture and Temperature Changes

Wood and laminate flooring shrink and expand with temperature and humidity changes. In doing so, the boards will slightly shift and create sounds such as cracking or popping. Without proper control of the room’s humidity levels, the incidence and volume of these sounds will intensify.

5. Wear and Tear

With time, floating floors inevitably undergo wear and tear. The locking systems between the planks tend to loosen, leading to the boards’ movement and making sounds. This happens particularly in high-traffic conditions.

Is It a Problem?

In most situations, Noise from floating floors is not a problem. A slight creaking or clicking occurs due to normal expansion and contraction or slight faults in the subfloor. However, if the sound is persistent or preceded by visible movement or gaps in the floorboards, it may be a more significant problem that requires attention.

How to Reduce Noise in Floating Floors

If your floating floor noise annoys you, here are a few valuable solutions to consider:

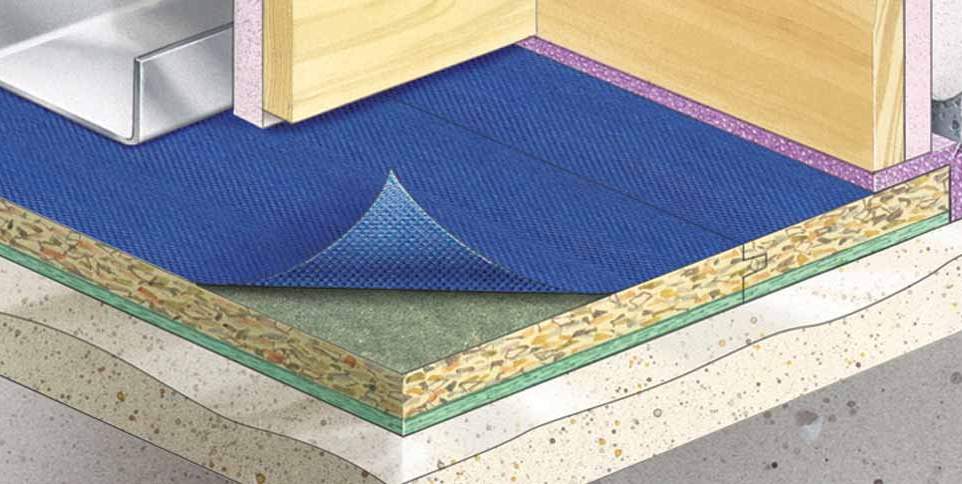

1. Acoustic Floating Floor

An acoustic floating floor has a special underlayment that dampens Noise and minimizes sound. An acoustic floating floor is perfect for a space where noise reduction is a concern, like apartments, offices, or multi-level homes.

2. Level the Subfloor

If the subfloor is not level, you can repair it by installing a self-leveling compound or sanding the high areas. A level subfloor will minimize movement and be less noisy.

3. Employ High-Quality Underlayment

Having a high-quality underlayment installed for floating floors will decrease Noise to a large extent. Foam or cork underlayment is a good choice for sound absorption and cushioning.

4. Maintain Correct Humidity Levels

Maintaining indoor humidity between 30% and 50% helps to avoid the over-expansion and contraction of floorboards, thereby minimizing Noise. A humidifier or dehumidifier can be used to ensure a consistent humidity level.

5. Secure Loose Boards

Loose or misplaced boards can be secured using adhesive or replacing the defective planks. This will remove creaking and make the floor more stable overall.

Conclusion

Yes, floating floors are expected to be noisy, mainly if they are new or laid over a subfloor with irregularities. Low-level creaking, popping, or clicking noises are generally not an issue and may often be sorted out by minor adjustments. Having an acoustic floating floor, installing it with proper underlayment, and keeping humidity levels consistent will also minimize Noise and enhance comfort levels. If the sound continues or worsens, a flooring specialist can be consulted to identify and resolve any problem.